Black Hex Head Screws Bolts, Alloy Steel, Grade 12.9, Black Oxide Finish, Fully Threaded, Standard

|

Product name

|

Black Hex Head Screws Bolts |

|

Material

|

Stainless Steel,Alloy,Carbon Steel,Brass,Aluminum and So on

|

|

Brand

|

JQS

|

|

Finish

|

Black Oxide Finish

|

|

Head Style

|

Hex

|

|

Size

|

M4-M30,or non-standard as request&design

|

|

Non-standards

|

OEM is available, according to drawing or samples

|

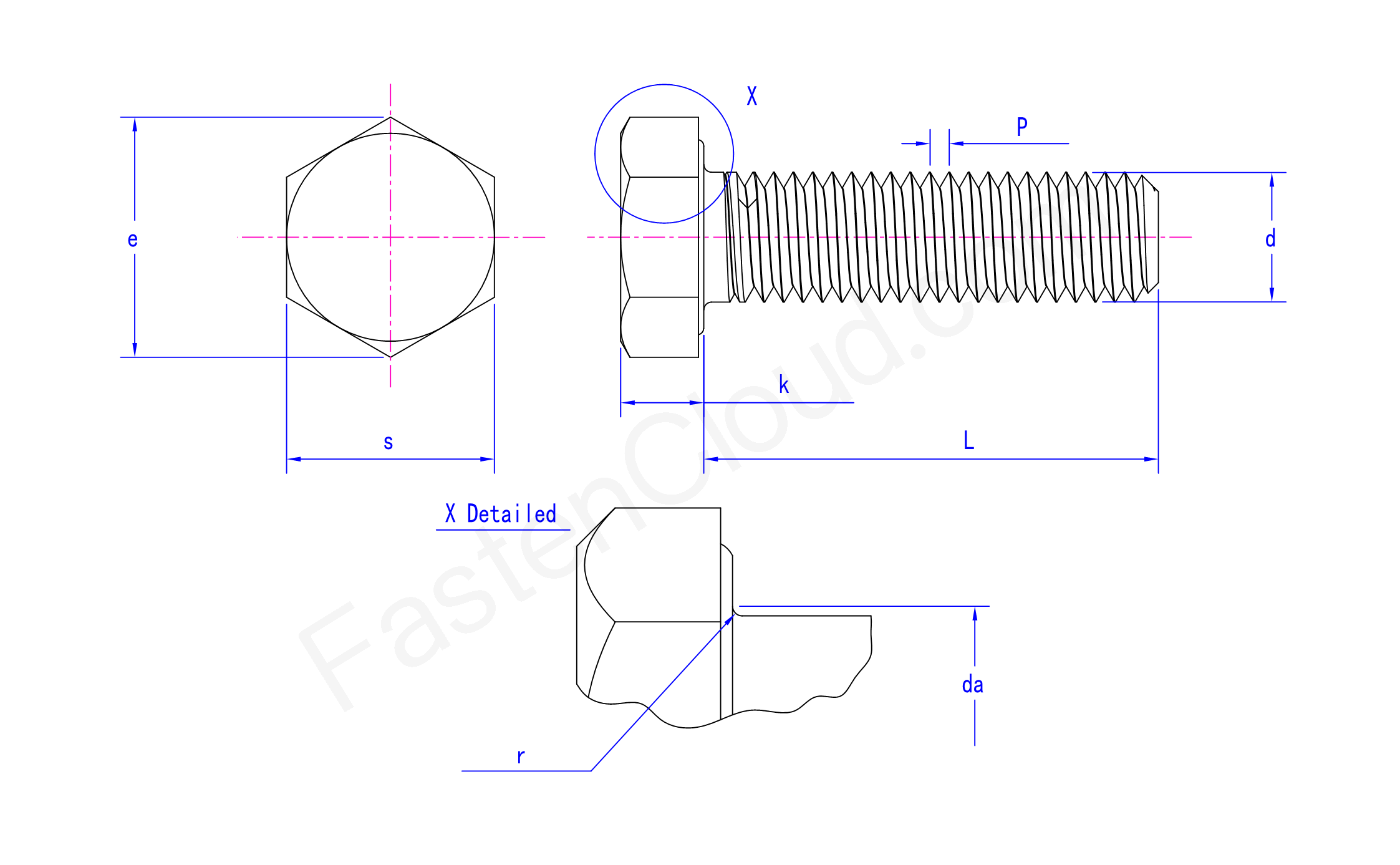

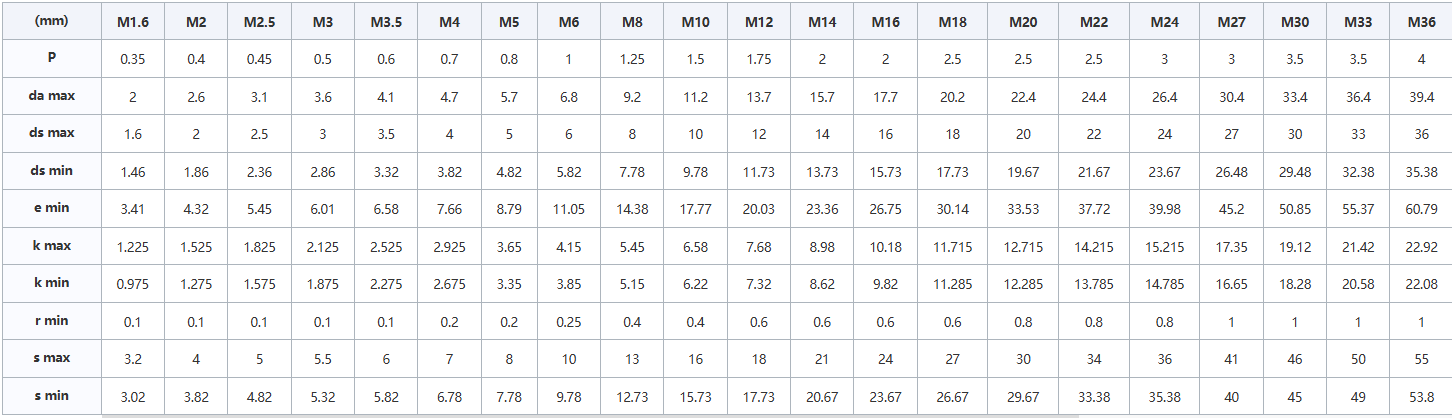

Parameter

Dear Customers,We understand the various concerns you may have when making a purchase decision. To ensure a worry-free shopping experience, we promise to provide you with comprehensive protection.

🔍 Sample Preview

Before production, we will provide samples for your inspection to ensure the product meets your expectations.

🌐 Global Logistics Partnerships

We have established partnerships with multiple international logistics companies to ensure your goods are delivered quickly and safely.

🛒 Hassle-Free Return Policy

If you are not satisfied with the product, as long as it meets our return conditions, you only need to contact us, and we will provide you with convenient return services.

📏 Customization Service

We offer customization services based on blueprints. Whether it's specific dimensions or special requirements, we can tailor-make it for you.

Choose us, and you choose peace of mind and trust. Place your order now and enjoy your exclusive shopping experience!

Hex screw bolt can be widely used in the home and office appliance, communication equipments, ship assembly and other machinery industry.

Made of alloy steel class 12.9, provides great strength.

Black finish, great protection against rust.

Thread Diameter: 10mm; Thread Pitch: 1.5mm; Screw Length: 35mm.

High-Strength Friction Grip Bolt

High-Strength Friction Grip Bolts offer higher preload and connection strength compared to standard bolts. They ensure the reliability and safety of connections by applying preload and utilizing static friction to resist shearing. High-strength bolts can be classified based on performance grade, material, structural form, and application field.

1. Performance Grade Classification

• High-strength bolts can be categorized into grades such as 8.8, 10.9, and 12.9, with higher numbers indicating greater strength. For example, grade 8.8 bolts have a yield strength of 800 MPa, while grade 10.9 bolts have a yield strength of 900 MPa.

2. Material Classification

• High-strength bolts are typically made of alloy steel, including carbon steel, alloy steel, and stainless steel. Carbon steel bolts are suitable for general connections, alloy steel bolts are suitable for high-strength and corrosion-resistant applications, and stainless steel bolts perform better in humid and corrosive environments.

3. Structural Form Classification

• Structural forms include fully threaded bolts, partially threaded bolts, and headed bolts, etc., suitable for different connection requirements and environmental conditions.

4. Application Field Classification

• High-strength bolts are widely used in construction structures, bridges, industrial equipment, aerospace, and other fields, designed and manufactured according to different needs.

Performance Requirements:

• Tensile Strength: The maximum bearing capacity of bolt material under tensile force, such as the nominal tensile strength of grade 10.9 bolts being 1000 MPa.

• Yield Strength: The critical stress value at which material transitions from elastic to plastic deformation under external forces, such as 640 MPa for grade 8.8 bolts and 900 MPa for grade 10.9 bolts.

• Yield-to-Tensile Ratio: The ratio of yield strength to tensile strength, an important parameter for measuring material ductility. For high-strength bolts, the yield-to-tensile ratio is typically between 0.8 and 0.9.

High-strength bolts are heavily consumed in China's construction structure field, accounting for about 60% of total production, mainly used for connecting steel structure beams and columns and seismic support systems. In bridge construction, the use of high-strength bolts in large structures such as suspension bridges and cable-stayed bridges exceeds 70%. In the industrial equipment field, high-strength bolts play a key role in connecting chemical equipment, heavy machinery, and pressure vessels. In the aerospace field, high-strength bolts are used to connect aircraft components, such as engines, wings, and landing gear, and must withstand the immense forces generated by high-speed flight and remain stable, requiring strict quality control and testing.

Introduction to Professional Fasteners

Fasteners are a class of mechanical parts that are widely used for fastening connections. In a variety of machinery, equipment, vehicles, ships, railroads, bridges, buildings, structures, tools, instruments, meters and supplies, etc., can be seen above a variety of fasteners. It is characterized by a wide variety of specifications, performance and use of different, and standardization, serialization, generalization of the kind of degree is also very high.

fasteners commonly used testing equipment

Fastener development and design is the most important part of the quality control, from the feed to the finished product shipments have several major gates, these major gates have different inspection methods. First of all, the incoming material is related to the appearance, size, elements, performance, harmful substances testing, etc.; the process is more appearance, size, knocking test, forging line; heat treatment is more appearance, hardness, torque, tensile, metallurgical, etc.; the surface treatment is more hydrogen embrittlement test, plating, salt spray, etc., including the shipment of a harmful substances testing. In the size, appearance testing, the common is the secondary element, contour measuring machine, three coordinate measuring machine, image sorting machine; mechanical and chemical testing, mainly hardness machine, tensile machine, metallurgical microscope; material testing, there is a spectral analyzer, salt spray testing machine.

it usually includes the following 8 types of parts:

1. bolts: 2. studs: 3. nuts: 4. wood screws: 5. Washers: 6. Retaining ring: 7. Pins: 8.Rivets

QingSong is a Professional Fastener Manufacturer Establishe

- Established in 1990, QingSong is a professional fastener manufacturer with 33 years' experience in production and R&D.

- Over the years, we have always been committed to providing our customers with high quality products and good service.

- We can produce and sell all kinds of standard fasteners and also customize all kinds of non-standard fasteners.

QingSong Fasteners International Exhibition Highlights

QingSong Innovation: Shop Floor, Storage, and Testing Fronti

EN

EN