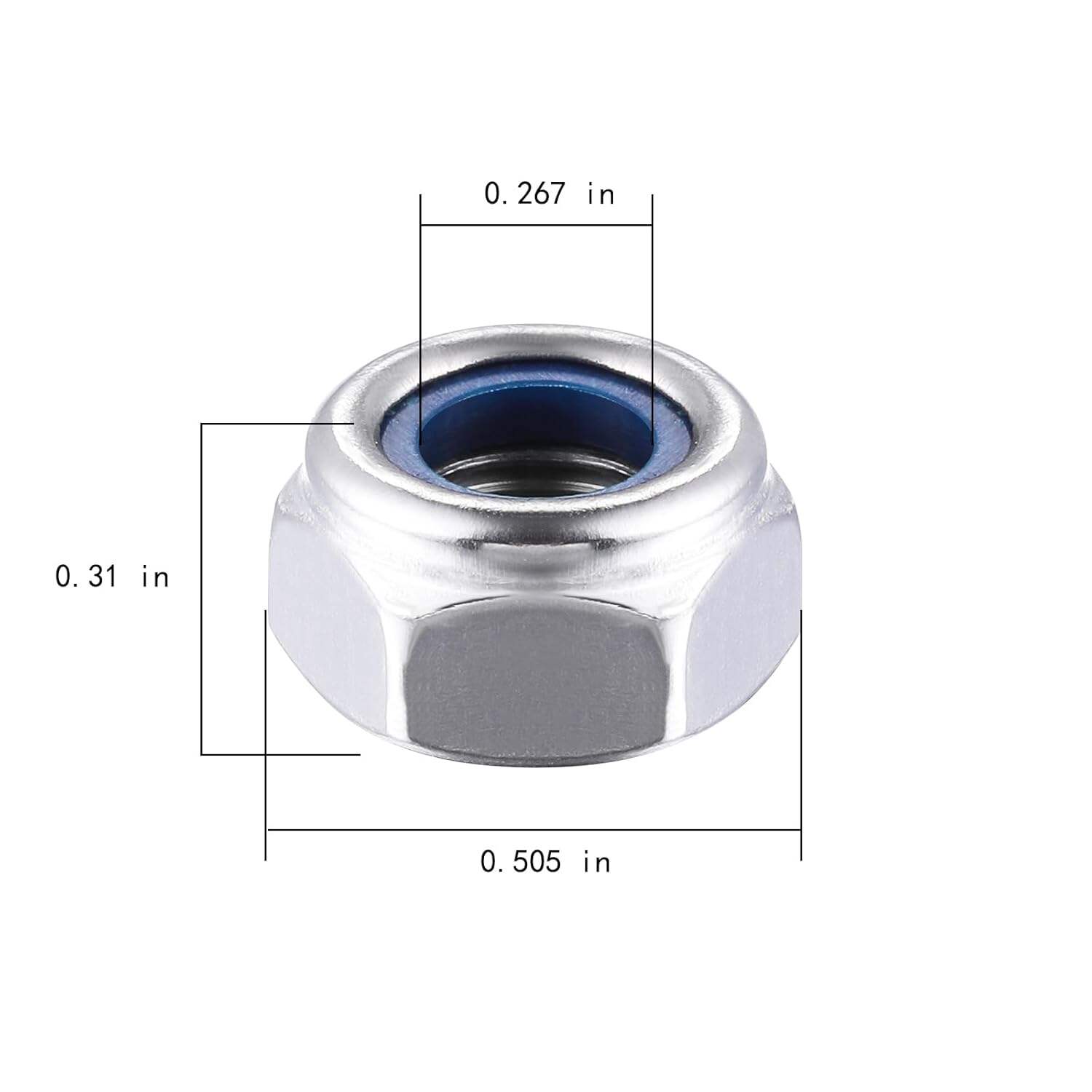

Nylon Inserted Hex Lock Nuts 304 Stainless Steel Silver

|

Product name

|

Nylon inserted hex lock nuts |

|

Material

|

Stainless Steel,Alloy,Carbon Steel,Brass,Aluminum and So on

|

|

Brand

|

JQS

|

|

Finish

|

Plain+oil,Zinc Plated,Black Oxide,Phosphate,Dacromet,Geomet

|

|

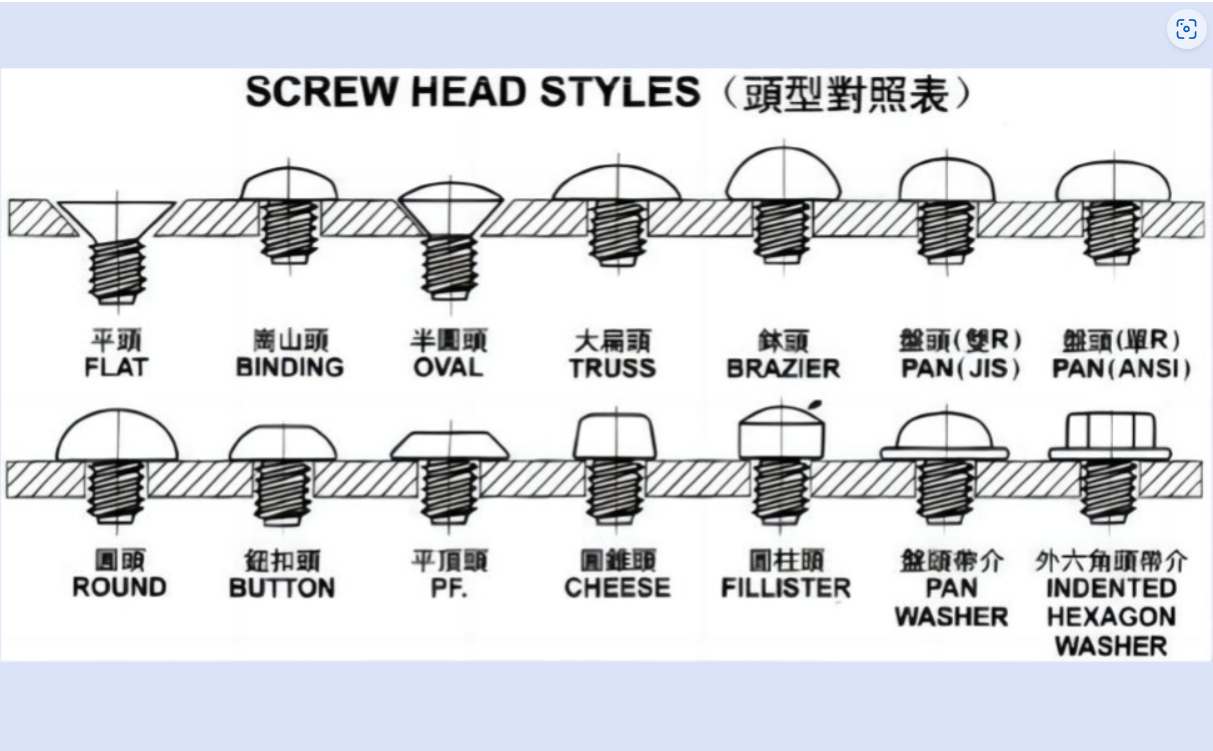

Head Style

|

Hex

|

|

Size

|

M4-M30,or non-standard as request&design

|

|

Non-standards

|

OEM is available, according to drawing or samples

|

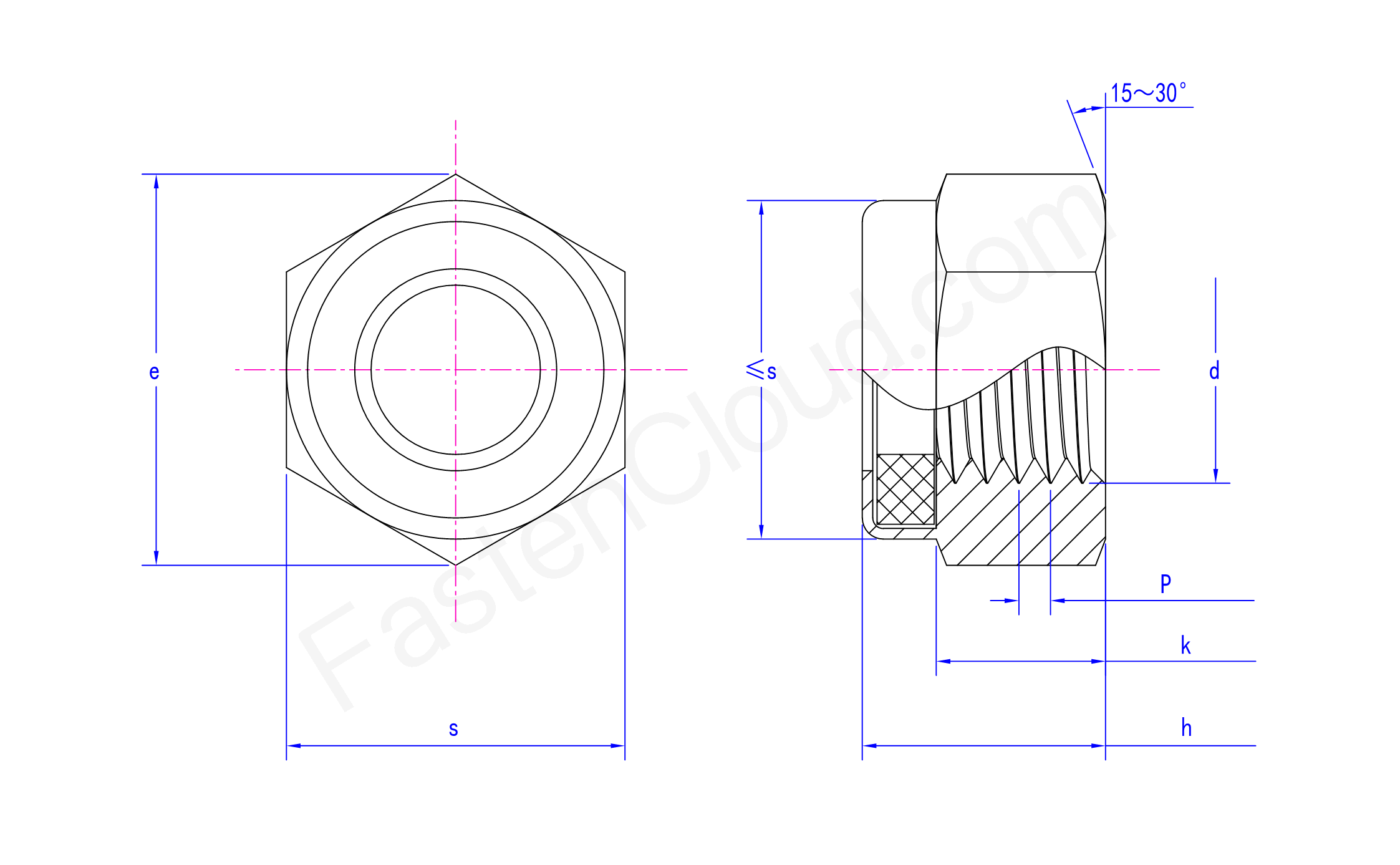

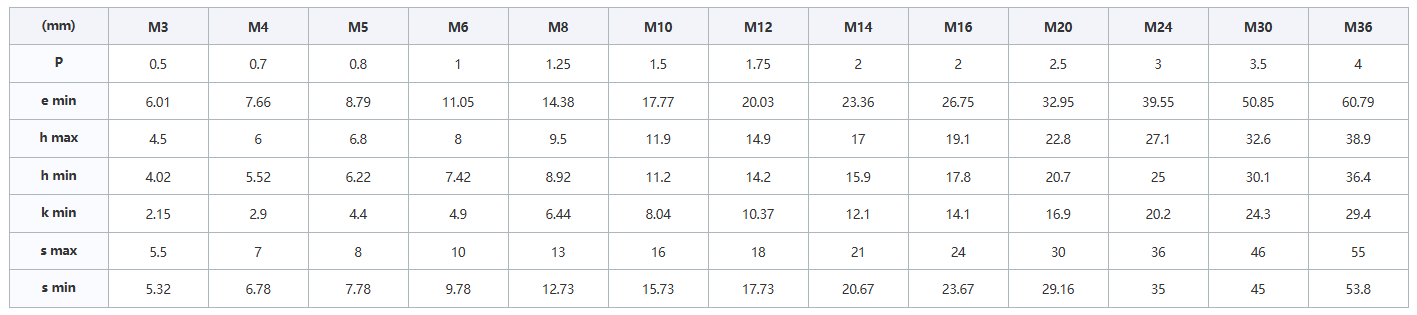

Parameter

Dear Customers,We understand the various concerns you may have when making a purchase decision. To ensure a worry-free shopping experience, we promise to provide you with comprehensive protection.

🔍 Sample Preview

Before production, we will provide samples for your inspection to ensure the product meets your expectations.

🌐 Global Logistics Partnerships

We have established partnerships with multiple international logistics companies to ensure your goods are delivered quickly and safely.

🛒 Hassle-Free Return Policy

If you are not satisfied with the product, as long as it meets our return conditions, you only need to contact us, and we will provide you with convenient return services.

📏 Customization Service

We offer customization services based on blueprints. Whether it's specific dimensions or special requirements, we can tailor-make it for you.

Choose us, and you choose peace of mind and trust. Place your order now and enjoy your exclusive shopping experience!

Nylon Insert Locknut: 1/4"-20 is standard inch threaded nylon locknuts have reliable anti-loosening performance, so that it and the bolt threads to form a close fit, and in the role of the elasticity of the nylon friction resistance, in order to achieve the purpose of anti-loosening. Assembly torque is more stable, anti-loosening is very reliable, can be used in shock vibration occasions

304 Stainless Steel Lock Nut: Nylon insert Lock nut is made of high-quality 304(18-8)stainless steel, rust-proof, corrosion resistance, sturdy, will not twist or deform, and has a long service life.With the spiral pattern is clear,the polishing process, the surface is smooth, no worry about scratching your hands

Wide Application: Common uses for inch hardware nuts include securing instrument and equipment components, linking pipes and structural elements.Suitable for use or maintenance in a wide range of applications such as furniture decoration, automotive repair, the mechanical industry and small repairsaround shops, construction, etc

Overview of Lock Nut

A Lock Nut,also known as a stop nut,brake nut,safety nut,or locking nut,is a specially designed nut primarily used to prevent loosening of threaded connections under conditions of vibration,impact,or other dynamic loads.A lock nut is a specially constructed nut that typically provides additional friction to prevent self-loosening.

Types of Lock NutsLock nuts can be categorized into the following main types based on their design and locking mechanisms

• Nylon Insert Lock NutFeatures a nylon insert that deforms when tightened,generating friction to prevent loosening.Suitable for standard threaded connections,especially in environments where anti-loosening is required.

• All-Metal Lock NutWithout a nylon insert,it provides locking by the plastic deformation of the metal,suitable for high-temperature or high-strength applications.

• Self-Locking NutHas a self-locking feature that prevents loosening through special thread design.

• Spring Lock NutContains a spring element that enhances friction through spring pressure,suitable for applications with frequent vibrations.

• Double Lock NutComposed of two nuts stacked together,they lock against each other to prevent loosening,suitable for high-strength connections that particularly require anti-loosening.

Characteristics of Lock Nuts

• High Coefficient of FrictionIncreases the stability of threaded connections by increasing the coefficient of friction,especially the nylon insert lock nut provides additional friction when tightened.

• Vibration and Impact ResistanceThe special design allows it to maintain connection stability in high vibration and impact environments,which is crucial for applications such as automotive and industrial machinery.

• Temperature AdaptabilityCertain types of lock nuts,like all-metal lock nuts,can adapt to high-temperature environments and are suitable for high-temperature applications such as engines and exhaust systems.

• Corrosion ResistanceTypically made from corrosion-resistant materials like stainless steel,allowing their use in corrosive environments such as chemical processing or marine applications.

• Ease of Installation and RemovalAlthough some lock nuts are difficult to install and remove,most are designed with ease of use in mind,making them convenient to use with standard bolts and screws.

• ReusabilityMany types of lock nuts can be reused if not damaged,but new anti-loosening washers or inserts should be used each time they are reinstalled to ensure connection reliability.

• EconomicalDue to their standardization and widespread application,lock nuts are generally cost-effective,making them an economical solution to enhance the safety and reliability of threaded connections.Please let me know if you need any further assistance or have additional requests

Introduction to Professional Fasteners

Fasteners are a class of mechanical parts that are widely used for fastening connections. In a variety of machinery, equipment, vehicles, ships, railroads, bridges, buildings, structures, tools, instruments, meters and supplies, etc., can be seen above a variety of fasteners. It is characterized by a wide variety of specifications, performance and use of different, and standardization, serialization, generalization of the kind of degree is also very high.

fasteners commonly used testing equipment

Fastener development and design is the most important part of the quality control, from the feed to the finished product shipments have several major gates, these major gates have different inspection methods. First of all, the incoming material is related to the appearance, size, elements, performance, harmful substances testing, etc.; the process is more appearance, size, knocking test, forging line; heat treatment is more appearance, hardness, torque, tensile, metallurgical, etc.; the surface treatment is more hydrogen embrittlement test, plating, salt spray, etc., including the shipment of a harmful substances testing. In the size, appearance testing, the common is the secondary element, contour measuring machine, three coordinate measuring machine, image sorting machine; mechanical and chemical testing, mainly hardness machine, tensile machine, metallurgical microscope; material testing, there is a spectral analyzer, salt spray testing machine.

it usually includes the following 8 types of parts:

1. bolts: 2. studs: 3. nuts: 4. wood screws: 5. Washers: 6. Retaining ring: 7. Pins: 8.Rivets:

QingSong is a Professional Fastener Manufacturer Establishe

- Established in 1990, QingSong is a professional fastener manufacturer with 33 years' experience in production and R&D.

- Over the years, we have always been committed to providing our customers with high quality products and good service.

- We can produce and sell all kinds of standard fasteners and also customize all kinds of non-standard fasteners.

QingSong Fasteners International Exhibition Highlights

QingSong Innovation: Shop Floor, Storage, and Testing Fronti

EN

EN